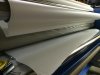

What a learning curve! Coming off our 38" Daige, to our new 63" USTECH has been one heck of an experience. So much more room for error when laminating 54" prints. We finally got it laminating 20ft runs without wrinkles after a bit of fussing with it, but I figured I'd ask about your tips and tricks for laminating large stuff.

How do you start it?

Do you always leave it webbed or do you raise the rollers once you're done?

Do you use a sled?

Let's hear it..most of our runs are about 3 to 25 feet so I don't want to waste 5 feet every time to get it running right

How do you start it?

Do you always leave it webbed or do you raise the rollers once you're done?

Do you use a sled?

Let's hear it..most of our runs are about 3 to 25 feet so I don't want to waste 5 feet every time to get it running right