-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Opportunity for new business...need advice please

stay away from used printers, if possible. nothing but threads of headaches on this forum. then again, same can be said about posts regarding the car racing graphics market. lol. stand your ground, set your timeline, & charge your rate. rush job demands will be common, & sponsorships for...- MikePro

- Post #13

- Forum: General Chit-Chat

-

-

Question liner to wrap and add logo to "air pots"

i've done a few of these for local gas stations & coffee shops. pick your poison vinyl, but since these are usually applied by the customer then I opt for air-egress/controltac/etc. Doesn't especially need to be cast, if you're looking for a better price-point ...as the graphic can wrap-around...- MikePro

- Post #6

- Forum: General Signmaking Topics

-

Huge Mistake, vinyl on paint

the devil is in the details.... stain resistance is resistance to adhesion. try vinyl designed for LSE plastics, like arlon 8000 or 3M IJ39 (edited to add some mad-scientistry: i've also made surfaces for receptive to adhesion via corona-treatment of the surface prior to application)- MikePro

- Post #20

- Forum: Installation Equipment & Techniques

-

How to properly align graphics on a car?

just tell your client that the graphics are only "crooked" because they have too much air in their rear tires.- MikePro

- Post #12

- Forum: Vehicle Graphics

-

Decorative Film & UV Tint install issues

the alcohol in your solution is causing your wet application to grab prematurely. no reason for it to be in there, unless you want something AGGRESSIVE. just soap & water & good application technique.- MikePro

- Post #6

- Forum: General Chit-Chat

-

ROLL-X or CWT questions

yes, you use these tables as your regular graphics table when not utilizing the roller feature. as for cutting/usage, we use our table a LOT. Heavy box-knife cuts of coroplast will take its toll, but regular xacto trimming of graphics barely make a dent in the surface. haven't replaced my...- MikePro

- Post #18

- Forum: General Signmaking Topics

-

Onyx Ink Limits

bad stock, or bad comms, or bad heads. ink limits are more of a quantity rather than a quality-thing.- MikePro

- Post #4

- Forum: RIP Software & Color Management

-

Insane installation

speaking a second language is the BEST, when people assume you dont know it. autotranslate & voice apps will make it all a breeze soon enough, and then amazon/google will have fullfilled yet another step in its master plan.- MikePro

- Post #17

- Forum: Installation Equipment & Techniques

-

Insane installation

we've mounted channel letters atop a flexface cabinet before.... the secret's in the sauce, but they're definitely not just "hung on the banner".- MikePro

- Post #16

- Forum: Installation Equipment & Techniques

-

ROLL-X or CWT questions

can you still wrap a car with a flat tire?- MikePro

- Post #14

- Forum: General Signmaking Topics

-

-

Need Help Bi-Directional issues

i think the hardest part is realizing the line doesn't move in your print adjustments... you just select the proper value and off you go. ....and I know this, because well, I did it too. Kept "chasing the line" and my values became so extreme that you would have though i attached a tattoo gun... -

Need Help Looking for shop to work with

Welcome to Signs101 Shouldn't be hard to find someone in your area, have you tried these guys?- MikePro

- Post #2

- Forum: Vehicle Wraps

-

Recommended Router Bits

Onsrud, Belin, & Armana have been great brands for me. Carbide Spiral O Upcut bits are worth the cost over plain steel bits, as they will last much longer & cut wonderfully. downcut bits aren't that great unless you've machined a "valley" around the perimeter of the shape you're downcutting...- MikePro

- Post #18

- Forum: CNC Routing & Laser Cutting

-

Mimaki Converted to Chinese Printer

I'm only experienced with the original machine you converted, and the original Epson printheads that were built-into it. whenever I had that level of haze on a printhead, I replaced it and the problem went away. i would be inquiring with the printhead/conversion supplier as to why these "brand...- MikePro

- Post #12

- Forum: Miscellaneous Printers

-

Mimaki Converted to Chinese Printer

nozzles appear to all be firing but the Cyan & Magenta appear to have a haze of ink around the pattern that could be causing your graininess.- MikePro

- Post #8

- Forum: Miscellaneous Printers

-

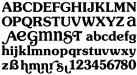

Souvenir Swash?

"Um waiter, I asked for NO SWASHES with my Lobster & Prime Rib. kthx"- MikePro

- Post #3

- Forum: Fonts and Typography

-

Time for a new printer

I print & cut on separate machines, which I think is still the optimal workflow. buuuut for anyone dead-set on a combo setup, anything and everything from mimaki has always made my pants shrink.- MikePro

- Post #36

- Forum: General Chit-Chat

-

Question Reflective Vinyl Peeling

yup, on black reflective vinyl lettering that was applied to sign panels a day or two after it was painted. curled corners & perimeter of ALL the 2-4" lettering on twenty or so double-sided 3'x4' sign panels. no laminate. so source of failure was entirely limited to paint & stock reflective...- MikePro

- Post #12

- Forum: General Signmaking Topics

-

Question Reflective Vinyl Peeling

heck, even autobody paint will declare 60-90days before you can wax a new paintjob before giving proper time for paint to cure. A bit much for sign purposes, but I'll usually give it a solid 3-4+days for reflective depending on time of the year. reflective vinyl traps solvent gases that...- MikePro

- Post #6

- Forum: General Signmaking Topics