-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

VersaCamm SP- 300 Print Head

Test the fuse (F3 i think) on the mainboard. If the fuse is bad then no signal is being sent to the head, chances are the head has a short and is blowing the fuse. My .02 GTSTech_1 -

-

Changing pinch rollers on sp300v

To change the pinchroller, simply remove the "C" washer/clip using needlenose pliers, push the pin out, replace with new roller, and re-attach the clip. Make sure the dot is on the outside, as the rollers are coned. Also don't replace the outer rollers with the removable rollers, they are not... -

-

Stripped head on screw while changing head on xc540, what now?

Not sure if the problem was solved. You might want to look under the print carriage.....what do you see? You would see the bottom of the 3 screws that secure the head, something the visegrips can get a hold of. My .02 GTSTech_1 PS- For the record, Roland doesn't train us on "Stripped... -

JV3 Triangle Ink Bulk System - Air in lines

Not sure what the question was but I can let you know "the old style" should read..... Carts, inkline, damper, head, captop, then pump. With the bulk it will be the same Bulk Tanks, inkline, damper, head, captop, then pump. My .02 GTSTech_1 -

Black prints fuzzy and with lines

Pinch the tubes (I use a paper clip) of the captop. Fill your caps with cleaning solution, after the machine gets back to it's home postion turn it off and unplug it. Let it sit for an hour, remove clips or whatever you used, run a medium clean cycle, if improvements (less deflection) repeat... -

roland fj 52

My guess is you didn't unplug the printer before installing the heads. Ribbons touched each other and fired either the servo board or the mainboard (I can't remember if they are separate boards or built in together). The stuck "Processing" message has been fixed with a replacement servo... -

Print Head trouble roland SP-300v

Reseat the ribbon cables at the printhead and printcarriage board, also inspect the contacts (look for dirty or bent contacts). My .02 GTSTech_1 -

no print from sp300v

Ditto what Bobby said. The fuse was shot on yellow/magenta, when you crossed the magenta it fried the fuse for the black/cyan. Check cables for burn marks, if present replace them as well. Just to make sure the cables are good, check continuity for each contact. My .02 GTSTech_1 -

roland sc-540 good bad ugly?

You might want to upgrade that flexi 7.0 to the 8.6. With 8.6 you can use the "Roland Color System Library". Sai revamped/redesigned the engine that drives the color output on the 8.5 (8.6). Another great feature of 8.6, if you had versaworks, would be the ability to send you file directly... -

roland sc-540 good bad ugly?

VersaWorks in my opinion is better when compared to ColorRip. I don't think Roland even updates ColorRip any longer, I know I haven't updated a ColorRip in 2 years. What Rip/Desiging program are you using for your Falcon? GTSTech_1 -

Sheet set error

Make sure your pinchrollers are within(under) the silver tab (grit roller slot). Reposition them see if it helps. Also check to see if you don't have a small piece of vinyl covering the sensor, at the same time I would clean the sensor eye (Rubbing Alcohol). My .02 GTSTech_1 -

roland sc-540 good bad ugly?

Along with the test prints as suggested by Compila, I would get a history report from the printer....alot of info on that (head shot, pump times, etc). Head should last up to 6 billion shots. The rip that came with the printer is ColorRip (it's a close cousin to Wasatch)....you can use... -

Best Flooring

Static buildup would be more of a concern than dust, when placing any electrical sensitive equipment on carpet. My .02 GTSTech_1 -

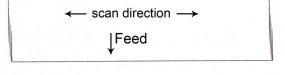

Print Cut Adjustments Off

Your pinchrollers could be worn out. Is there ink on the roller? Enough ink and it will soften the wheel, thus media skewing. -

Having a problem with the black on my 300v *with pics*

Your black has alot of "Deflection", which means when the head fires the jetted ink is not being layed down straight. The cause is dried ink, or something foregin in the nozzle channel. You said you filled the cap top with cleaning solution, but did you turn off the mainpower. You need the... -

printing problem sp-300

The skewing on the left and right side looks like a dirty encoder strip. The Overspray is usually the 1st sign of a head going bad. My .02 GTSTech_1 -

Versaworks 4.0

The 4.0 is geared more for the MT and LEC users, the versacamm and Pro users shouldn't see alot of changes. My .02 GTSTech_1 -

sp540 help

making a insurance claim could be the way to go. Your deductible is what? 1000? The Powerunit and labor to install is going to be close to that amount.....IF the problem is the powerunit (which it could be), but throw in a servo board, print carriage board, or whatever blew the powerunit and... -

sp540 help

Yes it's the "Powerunit"....but the bigger question is what blew the powerunit, it's why I recommend a Roland Dealer. They would be able to replace the powerunit if it blows again (I'm talking about initial install of new board), if the short rears it's ugly head.