nolanola

https://manhattansignshop.nyc/

Hello forum.

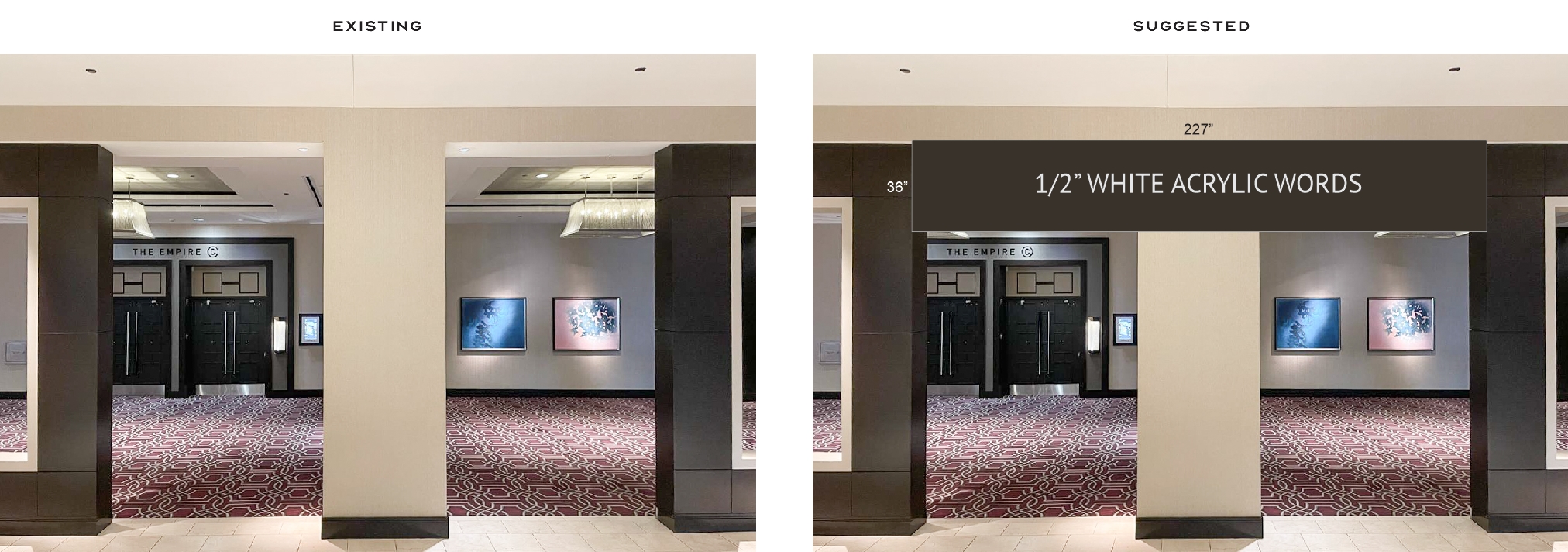

We are going to produce and install a large polycarbonate panel. I'm looking for a advice on two questions:

1. Our client has requested that we match the panel's color with that of a brown wall, which has been coated with latex paint. To avoid the complexities of calibrating our printer to match this specific shade of brown, I'm considering applying the same paint directly to the panel. However, polycarbonate panels are notoriously tricky for latex paint adherence. Could wrapping the panel in an adhesive wallcovering material and then applying the paint with a roller be a viable solution? If so, what material would be most suitable for this approach?

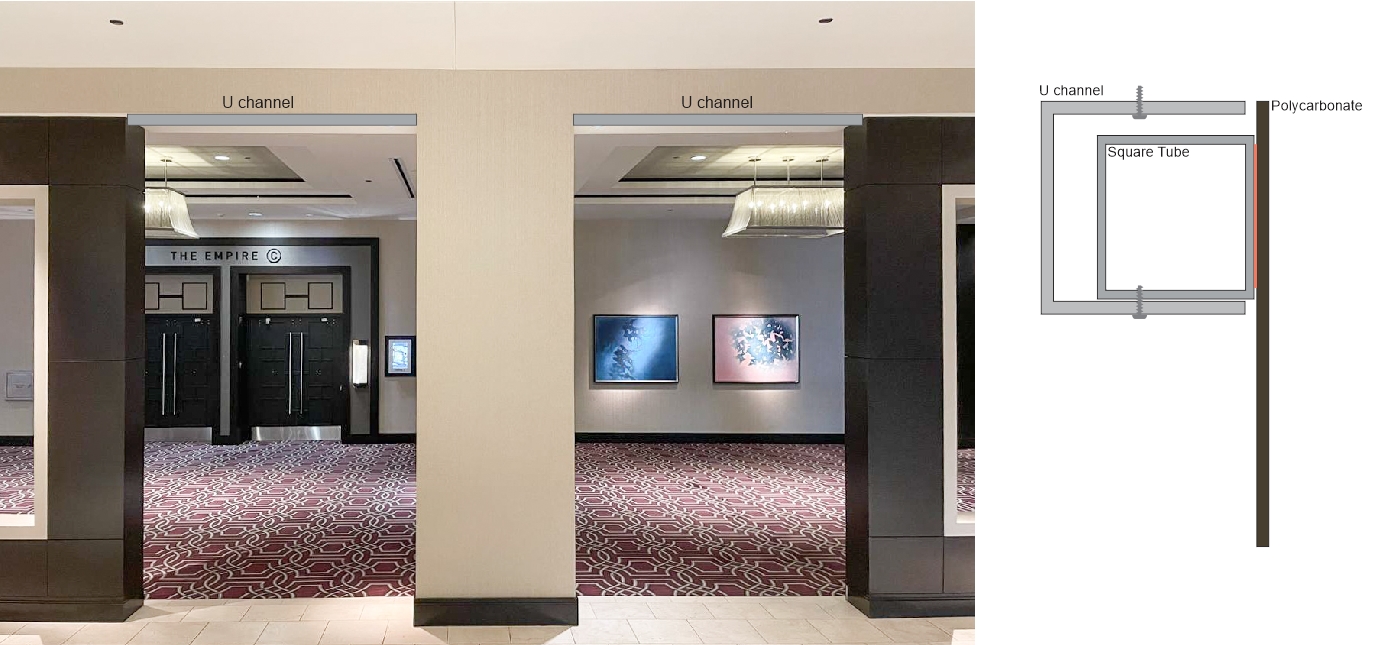

2. Regarding the installation, I'm contemplating a method to secure the panel by affixing a 2"x2" square tube to its back and then attaching a slightly larger U-channel to allow the tube to slide in, which could then be fastened with screws. I suspect there might already be established solutions similar to this. Do you have any recommendations or proven methods for this kind of setup?

Thank you.

We are going to produce and install a large polycarbonate panel. I'm looking for a advice on two questions:

1. Our client has requested that we match the panel's color with that of a brown wall, which has been coated with latex paint. To avoid the complexities of calibrating our printer to match this specific shade of brown, I'm considering applying the same paint directly to the panel. However, polycarbonate panels are notoriously tricky for latex paint adherence. Could wrapping the panel in an adhesive wallcovering material and then applying the paint with a roller be a viable solution? If so, what material would be most suitable for this approach?

2. Regarding the installation, I'm contemplating a method to secure the panel by affixing a 2"x2" square tube to its back and then attaching a slightly larger U-channel to allow the tube to slide in, which could then be fastened with screws. I suspect there might already be established solutions similar to this. Do you have any recommendations or proven methods for this kind of setup?

Thank you.