PixelImola

New Member

Hello,

We are having problems with the plotter : Mimaki UCJV300-160.

It is practically new and still covered by warranty.

The dealer is, as yet, unable to help.

A brief summary of our main problem is as follows:

Could anyone please comment or suggest a possible solution, or remedy, for this unusual, and most unfortunate, condition ?

A few examples of some test prints using this plotter and some comparisons with one of our other plotters, a Roland XR-640, which prints correctly are attached below.

In addition to this we cannot find a way to enable the Remote Access Mode on this plotter.

ie Web Management via IP and Browser Interface, which is normally present in nearly all professional machines. We believe that this option is available for this model since one of our staff saw it enabled on another Mimaki plotter, (with the same model and the same firmware) and visible in the display menu.(Network) of the plotter.

Is anyone aware of other options available for remote management (SNMP, etc) of this plotter ?

Thank you.

We are having problems with the plotter : Mimaki UCJV300-160.

It is practically new and still covered by warranty.

The dealer is, as yet, unable to help.

A brief summary of our main problem is as follows:

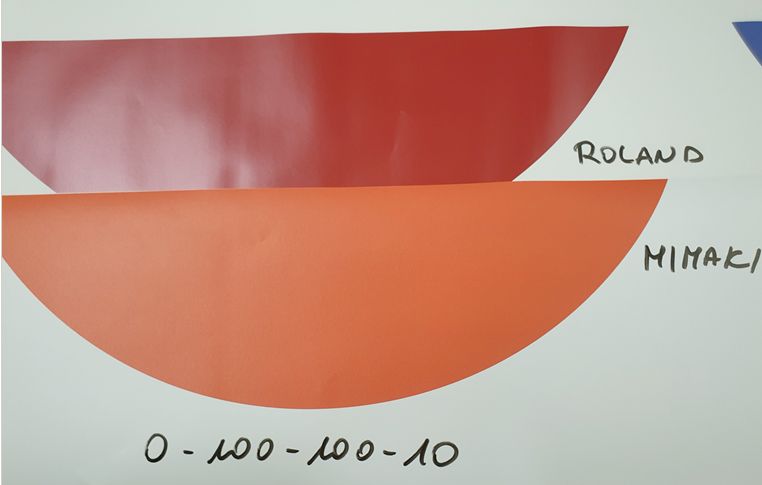

- The plotter will not print red correctly, the hues are faded or worse, are altered to the point of becoming literally orange, in particular at lower resolutions.

- A Mimaki technician tried creating a custom profile to resolve the question, which was to no avail.

(the plotter should print a full red even from the plotter’s own test print, without a custom profile) - Maintenance tests and an air purge have been performed on the plotter.

- It seems that there is, at present, no Firmware update available from Mimaki for this plotter.

Could anyone please comment or suggest a possible solution, or remedy, for this unusual, and most unfortunate, condition ?

A few examples of some test prints using this plotter and some comparisons with one of our other plotters, a Roland XR-640, which prints correctly are attached below.

In addition to this we cannot find a way to enable the Remote Access Mode on this plotter.

ie Web Management via IP and Browser Interface, which is normally present in nearly all professional machines. We believe that this option is available for this model since one of our staff saw it enabled on another Mimaki plotter, (with the same model and the same firmware) and visible in the display menu.(Network) of the plotter.

Is anyone aware of other options available for remote management (SNMP, etc) of this plotter ?

Thank you.