-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Cleaning Aluminium Composite Material (ACM) for UV printing

+1 for this.- SignMeUpGraphics

- Post #11

- Forum: Tips & Tricks

-

-

Cleaning Aluminium Composite Material (ACM) for UV printing

The SAS stuff comes off slightly easier than Signbond I've found. Only trick is to try peel it off in one smooth motion or you'll get lines in lighter areas of print. We use 70% isopropyl/distilled water mix, and just keep rubbing until there is nothing left. As Gino says, do not let the iso...- SignMeUpGraphics

- Post #5

- Forum: Tips & Tricks

-

Question Installing Versaworks to Secondary Drive

Okay, what you can try is this: Shutdown Versaworks and move "C:\ProgramData\Roland DG VersaWorks" (let's take the entire parent folder over) and "C:\Roland" to the root of the SSD drive. I will assume this is D:\ but feel free to modify the below commands to suit: mklink /j...- SignMeUpGraphics

- Post #8

- Forum: Roland

-

Question Installing Versaworks to Secondary Drive

They don't offer it from memory. Assuming you're using Windows you'll be best off creating a junction point to the new drive and "tricking" Versaworks to install there. https://www.howtogeek.com/howto/16226/complete-guide-to-symbolic-links-symlinks-on-windows-or-linux/ What is the default...- SignMeUpGraphics

- Post #4

- Forum: Roland

-

What do you print on when a client requests posters

Sihl 3672 (200gsm) or 3673 (130gsm) for matte poster prints. Both are cheaper than any vinyl we stock.- SignMeUpGraphics

- Post #19

- Forum: Digital Printing

-

Need Help Oce Arizona 318GL Gantry Issue

Are all of the emergency stop buttons fully released?- SignMeUpGraphics

- Post #3

- Forum: General Chit-Chat

-

OCE Arizona 365GT no white ink at all now?

Is the reservoir status showing full on the Ink System Status page? If you perform several purges to get it to show "Low" then close the ink bay drawer can you hear the white pump refilling the reservoir?- SignMeUpGraphics

- Post #2

- Forum: Flatbed Printers

-

Changing Ink Configuration:: VS540i

Are they both the same model printer running the same firmware version?- SignMeUpGraphics

- Post #2

- Forum: Roland

-

Need Help Anyone know where to get the material to make this curb sign..looks cool!!!

AUD $3,150 for a 45m roll over here (USD $2,250 for 50 yards)- SignMeUpGraphics

- Post #13

- Forum: Labels and Decals

-

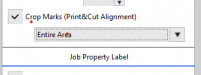

Question Crop Marks - For Each Row - Versaworks 6

Been a while since we had our Roland but I think we made the roll length the same (or slightly longer) than each row of the job. It would then put a fresh set of marks around each row as it went down the page.- SignMeUpGraphics

- Post #2

- Forum: RIP Software & Color Management

-

Need Help Anyone know where to get the material to make this curb sign..looks cool!!!

https://www.alumigraphics.com/- SignMeUpGraphics

- Post #4

- Forum: Labels and Decals

-

Laminate overhang!

How did you end up with this project?- SignMeUpGraphics

- Post #25

- Forum: General Signmaking Topics

-

Question Is there a Graphtec FC8600 video demonstration start-finish?

Rotate in CutServer works perfectly well for us in 12.2- SignMeUpGraphics

- Post #4

- Forum: General Chit-Chat

-

-

Question Is there a Graphtec FC8600 video demonstration start-finish?

Load the media, use the platen as a guide to getting your print straight. You can do it be eye or feel by putting a finger over each crop mark and moving it until it feels close to straight. Depending on how much lead material you have, you can either use roll mode 1 (which spools right to the...- SignMeUpGraphics

- Post #2

- Forum: General Chit-Chat

-

Onyx 12.2 Quickset question

Holy hell what a workaround... but I will confirm that it worked on our 12.2! Well done for working that one out.- SignMeUpGraphics

- Post #6

- Forum: RIP Software & Color Management

-

Onyx 12.2 Quickset question

Closest I could get was to specify a 16px black line in the "Bleed Marks" configuration section (lower right of the Bleed page). Not sure how thick this will print without doing a test. Other than that, it seems like Onyx have decided that white or first pixel are the only options available.- SignMeUpGraphics

- Post #3

- Forum: RIP Software & Color Management

-

Is our laminator "worn out"? Need feedback! Royal Sovereign

We have the heat assist version of the same laminator. The top roller moves easily 1/4"-1/2" upwards in the open position and we don't have any bubbling issues. We typically nip the roller down until it rests on the substrate, then lock it down one position tighter.- SignMeUpGraphics

- Post #7

- Forum: Laminators

-

Not a new member

Pretty sure it shows New Member due to low post count. Nothing to do with age of the account.- SignMeUpGraphics

- Post #6

- Forum: General Chit-Chat

-

How to add cut line & bleed to existing design

Thanks for the replies and effort so far. The video was far more than I expected. Shame we don't use Flexi, as it looks to be a notch above Illustrator in this instance. I think we'll have to resign to ewded's suggestion on this one. Just found out that the install is going to be nearly 8 feet...- SignMeUpGraphics

- Post #4

- Forum: Designs & Layouts