Aardvark Printing

New Member

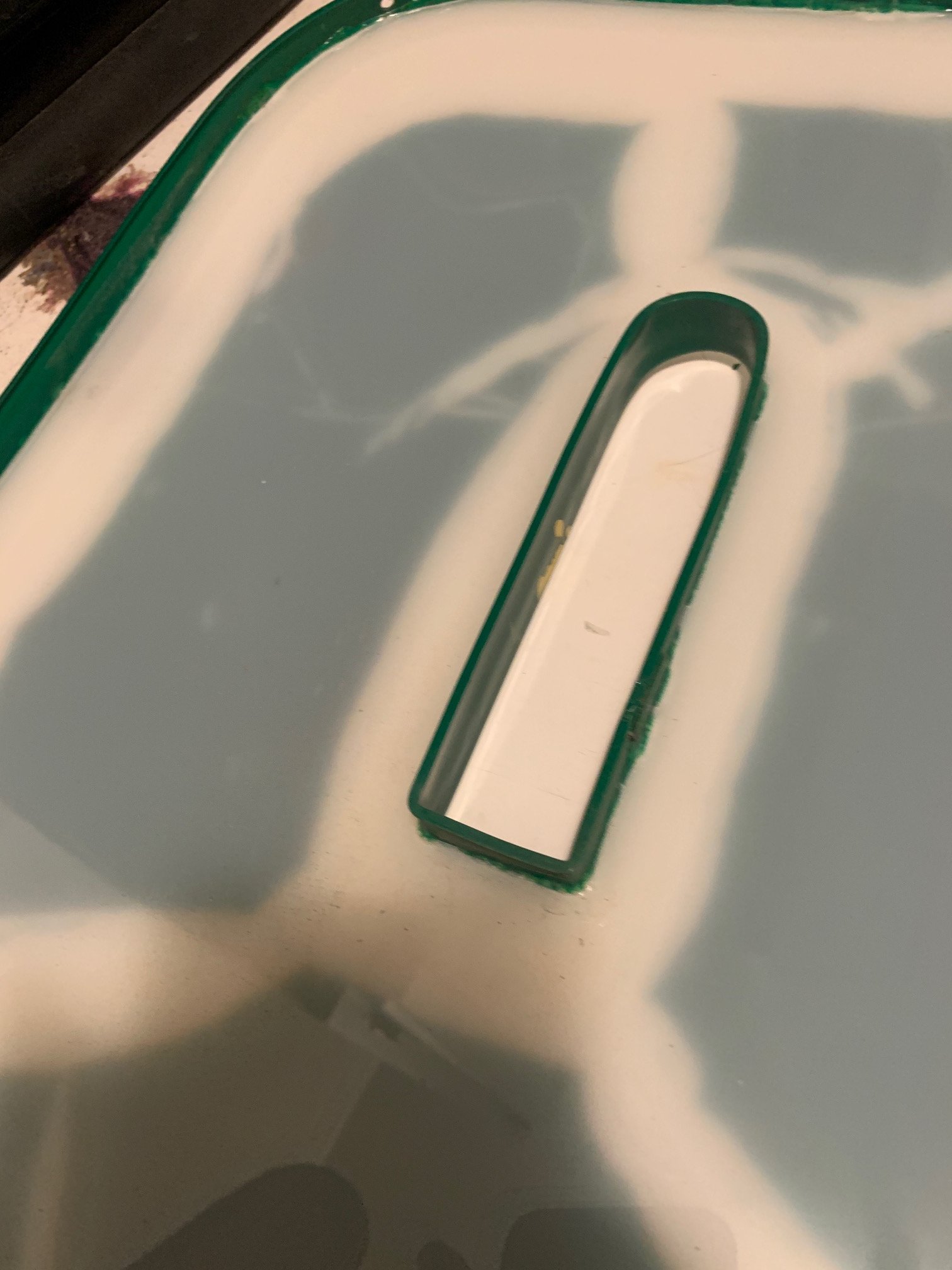

I'm replacing the vinyl in a customers channel letters that has dried and peeled. I'm using 3M Scotchcal series 3630 for the lettering.

Any advice on applying the new vinyl and does it need to be laminated?

Any advice on applying the new vinyl and does it need to be laminated?