signage

New Member

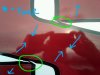

Rob sunlight and UV are one issue but we have wide temperature swings that also have different effects on the vinyls/adhesives. Also what you are seeing could be caused by the temperature swings that the vinyl is seeing! Remember the the flat sign doesn't get any heating from the other side while the vehicles get warmed up from the inside out during our winter months! So that may have caused the issue with the vehicles while the sign isn't experiencing it!